1.Room Pressurization:

The main task is to prevent air, dust, contaminants … from the room, the dirtier area to the room, the cleaner area. The basic principle of air movement is from high pressure to low pressure. So rooms with a cleaner level have higher pressure and vice versa. To control the room pressure, there is usually a pressure gauge, when the room pressure is exceeded, it will automatically spill out through the air outlet (Pass-Through Grilles). Usually, rooms with high requirements are connected with the wind mouth.

The pressure created in the room when designing must take care of the fan head and the difference between air supply and return air in a clean room.

In designing a pharmaceutical factory according to WHO-GMP (World Health Organization-Good Manufacturing Practice), the pressure levels are + (15Pa), ++ (30Pa), +++ (45Pa), respectively.

2.Cleanliness:

The cleanliness of the room is determined by two factors: the Air Changes per Hour and the Filter.

Typically for air conditioning for office buildings can be 2 to 10 times. But in a clean room system, the air changes per hour is up to 20 times, especially in a clean room for chip production up to 100 times. Increasing the air exchanges per hour to reduce the concentration of dust particles and pollutants generated in clean rooms. Therefore, the cleanroom structure is different from office buildings. For rooms with different cleanliness requirements, the number of air exchanges is also different. For example, in a pharmaceutical factory in a dressing area of grade E (black grade), the room pressure is + (15Pa), the number of wind exchanges is 10, while the mixing room has grade C with room pressure ++ (30Pa), the air changes per hour is 20, filter level H12.

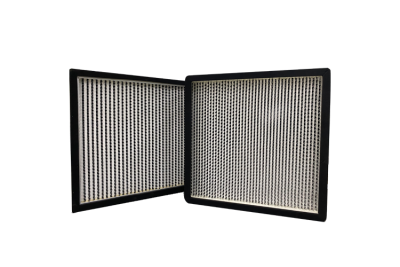

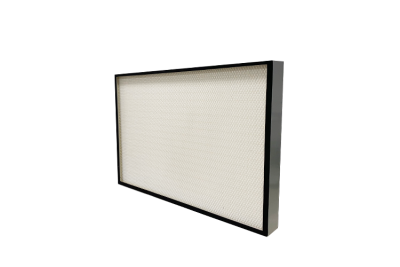

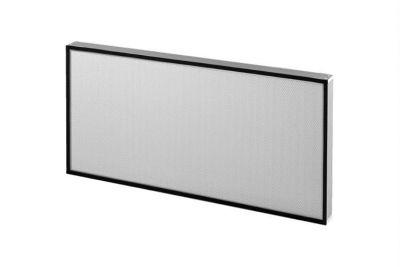

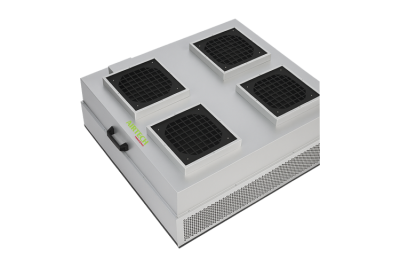

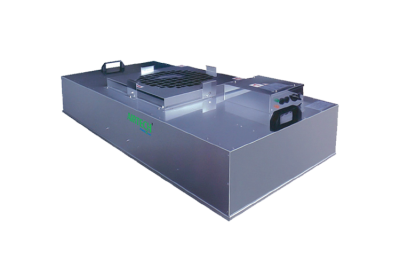

The filter has the task of filtering dust particles of the air before entering the room. Depending on the requirements of the clean room types, use filters accordingly. Usually with rooms in the pharmaceutical factory, use high efficiency filter type HEPA (High Efficiency Particle Air). Filter positions can be mounted either at the AHU or from each room.

3.Cross-Contamination:

To understand cross-contamination, we define the contamination. Contamination is the unwanted infection of impurities of a chemical or microbiological nature, or foreign particles entering or onto a starting material or intermediate product during the manufacturing process, sampling, packaging, storage and transport. Cross-contamination is thus the infection of a starting material, intermediate product, or finished product with a starting material or other product in the manufacturing process.

Cross contamination has both external and internal causes. The following is a summary of the main factors of cross-contamination in the pharmaceutical factory.

The problem of cross-contamination is quite complicated for the rooms of the pharmaceutical factory as well as the operating room in the hospital. Clean rooms for hi-tech are much less because only one product is produced in a large area. In fact, Vietnamese pharmaceutical factories produce too many different drugs in the same room, so the level of cleanliness is very high and the cross-contamination problem becomes difficult to control. The solution to cross-contamination is to solve the above 10 problems, plus the creation of pressure in a clean room.